Our Process

Our primary raw material source for banana paper manufacturing is banana steam. After the farmers have harvested the fruit from the banana plant, the stem is cut into small pieces and soaked in a vat overnight. The fiber is then cooked with wood ash or caustic soda solution. The soften bark washed out with water after boiling to remove impurities. The cooked pieces of the banana trunk are then placed in a Hollande beater and beat into a fine pulp.

Once this process is completed the pulp is put in a vat, and a mold is used to draw the pulp from the vat to form sheets. The sheets in its wet phase are laid out to dry in the sunlight until thoroughly dried. The layer of pulp becomes sheets of paper after drying and is peeled slowly from the boards

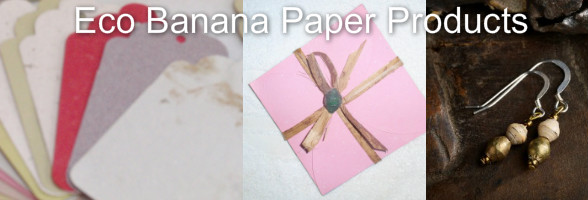

Photo Gallery: Our Products

The image gallery is empty.